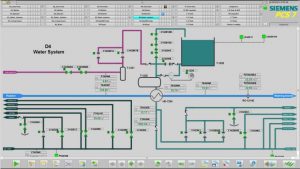

N2O plant

Nitrous Oxide Production Plants

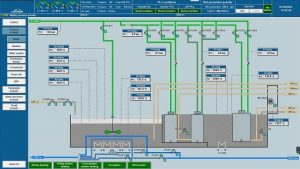

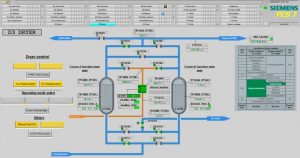

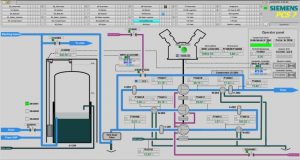

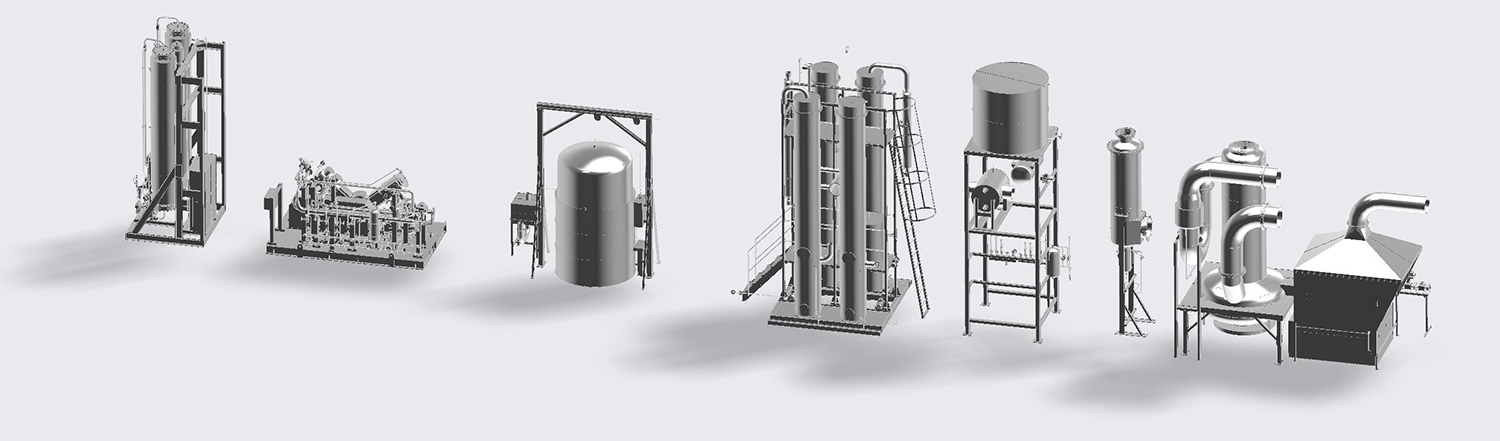

Melter

Reactor

AN filter

Condenser

Washing towers

Gasholder

Fine dust filter

Compressor

Dryer

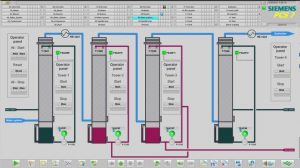

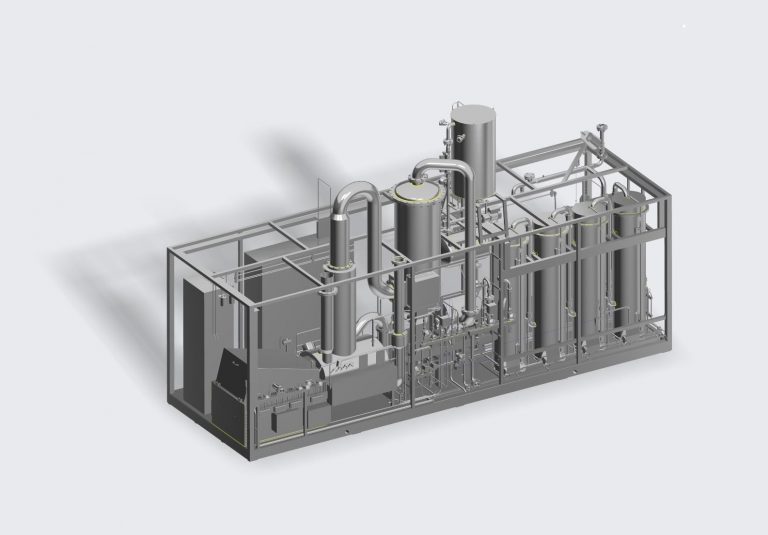

Modular, Skid-mounted equipment

Skid mounted means that the plant units are fixed on a platform and covered with a frame. The units are connected, and the control system also included into the frame. The installation and start-up require the local utilities and the raw materials.

M80

80 kg N2O / hour

650 tons/year

M50

50 kg N2O / hour

400 tons/year

M25

25 kg N2O / hour

200 tons/year

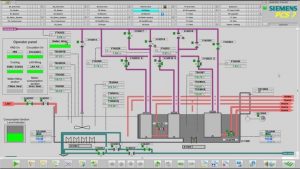

Separated units equipment

Separated elements means that the plant units have a fix dimensions, but the layout of the complete plant roughly free owing to the different length ad shape of the connection tubes between the units. The installation and start-up process are require more time and some of the connections are only finished on Customer’s site

S300

300 kg N2O / hour

2500 tons/year

S200

200 kg N2O / hour

1600 tons/year

S130

130 kg N2O / hour

1000 tons/year

Standard production Quality

This grade is suitable for Medical purpose or for further

purification with Ultra High Purity unit.

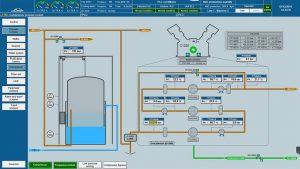

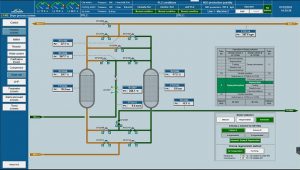

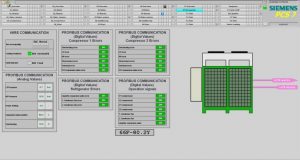

Control system of the Equipment

Relay:

Basic version is using

“Relay” control logic

Relay/Digital:

Hybrid unit – Relay controll

+ PLC monitoring + Digital reaction control

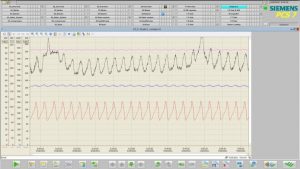

Digital/SIL:

Advanced version is

controlled by “PLC” and has

(Safety Integrity Level)

SIL II safety

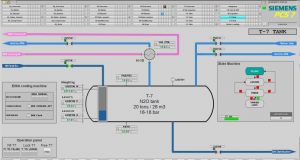

Produced gas Pressure

Low Pressure Compressor

and Drying unit

16…20 barg

(operation pressure: 17…19 barg)

High Pressure Compressor and Drying unit

45…70 barg

(operation pressure: 50…65 barg)

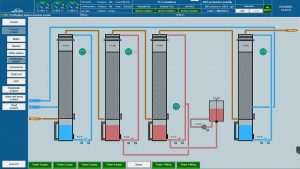

Raw material

Solid Ammonium Nitrate

25…50 kg bags

2,02 kg SAN / 1 kg N2O

Optional automatic SAN feeding system

Liquid Ammonium Nitrate

20…40 tons storage tank

2,25 kg LAN / 1 kg N2O

Optional LAN storage and feeding equipment

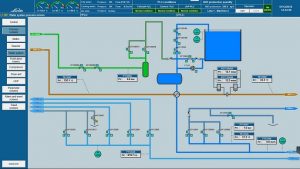

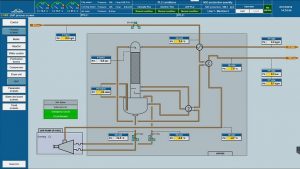

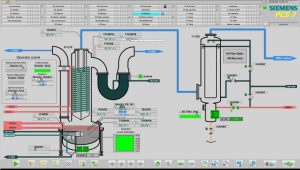

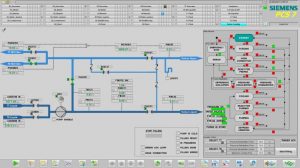

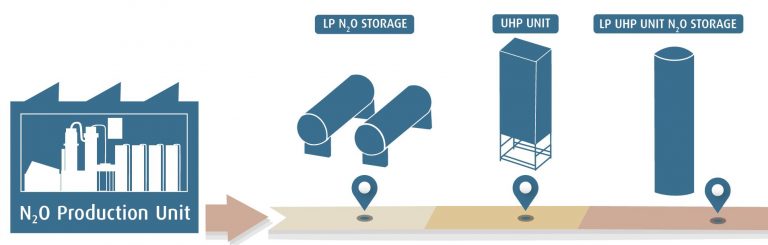

Nitrous Oxide Ultra High Purification Units

The electronic industry requires Ultra High Purity quality Nitrous Oxide. The Ultra High Purification Unit is normally connected to a N2O production plant and it is purify its product to an UHP Storage tank.

LP N2O Storage

UHP Unit

LP UHP Unit N2O storage

Ultra High Purity

UHP350

350 kg N2O / hour

2500 tons/year

UHP250

250 kg N2O / hour

1600 tons/year

UHP120

120 kg N2O / hour

1000 tons/year

The nitrous oxide from the Low Pressure storage contains approx. 0.2 – 0.5 Vol. % nitrogen and oxygen. At the top of the rectification column, the impure fraction of N2O sent back to the gasholder contains approx. 4 – 8 % (V/V) N2 and O2, depending on feed purity. These non-condensable gases will be eliminated by the venting of the storage tanks of the existing N2O plant. At the bottom of the column UHP nitrous oxide with a purity above 99.999 Vol. % N2O is pumped into a UHP low-pressure tank.

The UHP unit has 3 main unit. The Cold-box and the UHP pump has a fix layout, and the Vaporizer with the Vent panel have freedom in case of limited available space.

Ultra High Purification quality

This grade is for electronic industrial purposes.